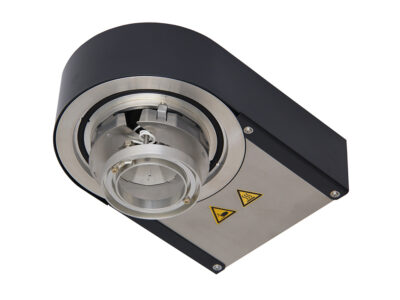

Safematic standard vacuum carbon coater

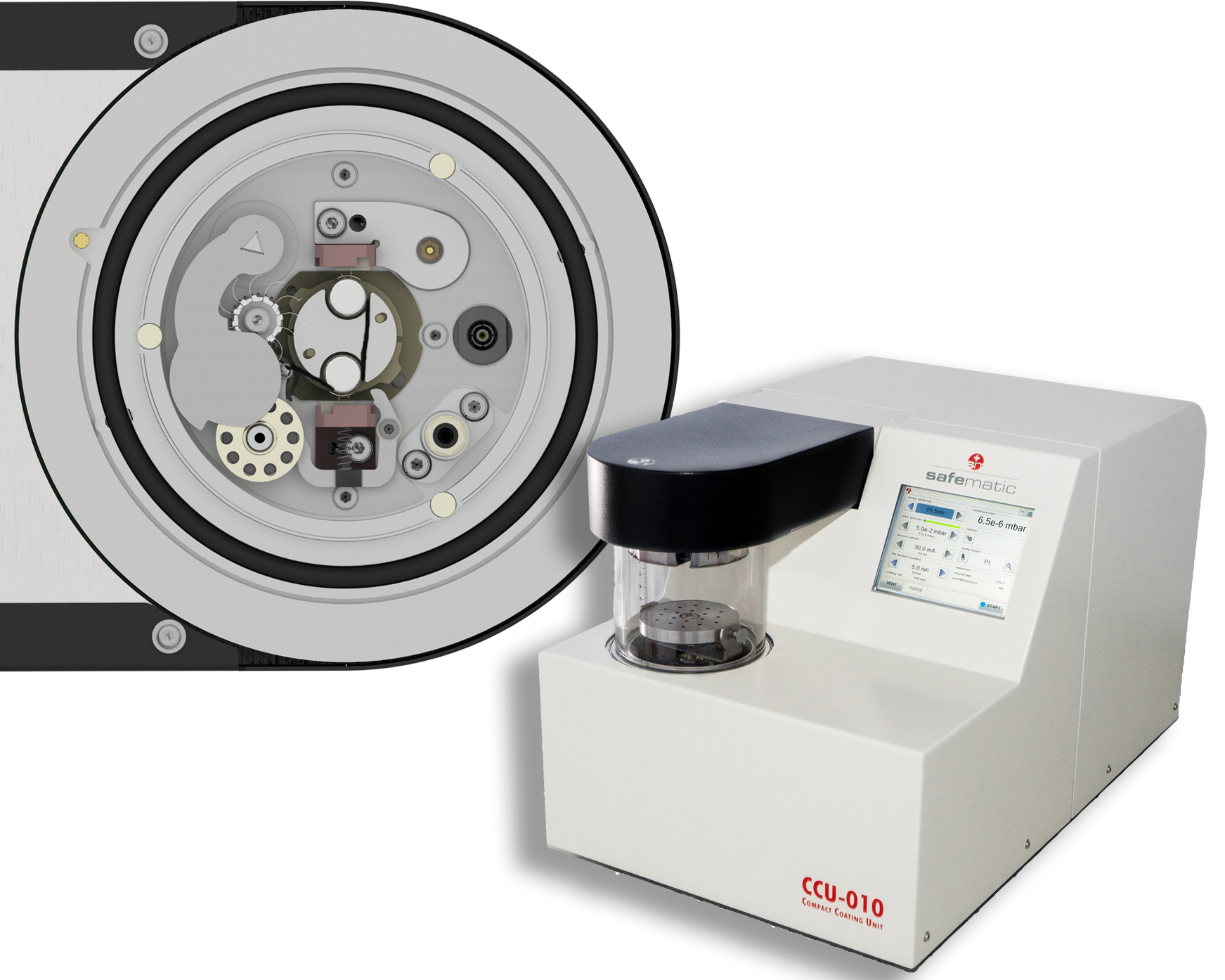

Safematic CCU-010 LV is a standard vacuum (rotary pumped) carbon coater, primarily designed for coating SEM specimens for EDS and WDS. For high resolution SEM and TEM carbon applications the high vacuum CCU-010 HV is recommended.

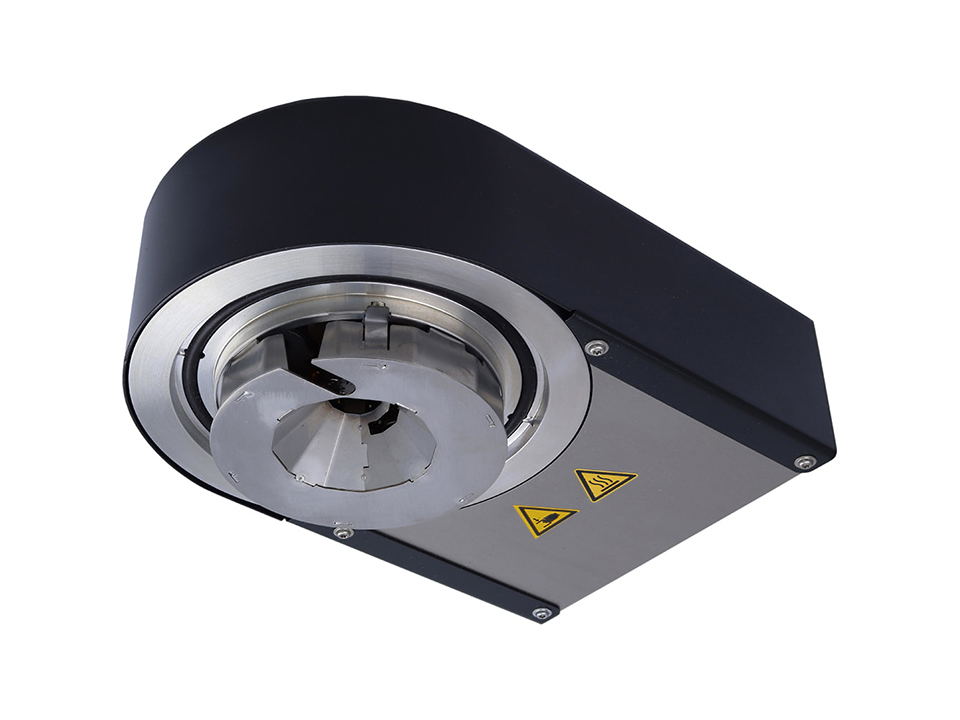

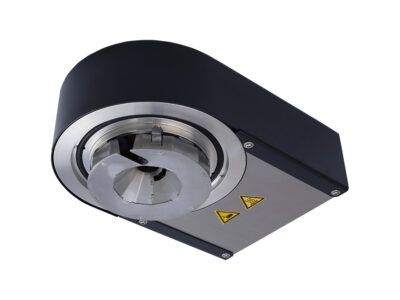

The CT-010 is a compact, self-contained, carbon evaporation head module which plugs into the CCU-010 LV base unit. A stand-out highlight of the CT-010 is its evaporation capabilities – featuring a multi-coating, automatic carbon fibre spooling system.

The CT-010 carbon coater module precisely controls carbon film thickness and terminates evaporation at user-defined thicknesses. The process uses the on-board quartz film thickness measurement system in combination with pulsed carbon evaporation to track the increase in carbon film thickness. It then adjust the evaporation current as it nears the user-defined carbon coating thickness, typically in the range of 2-15nm for EM applications.

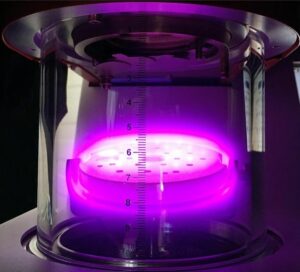

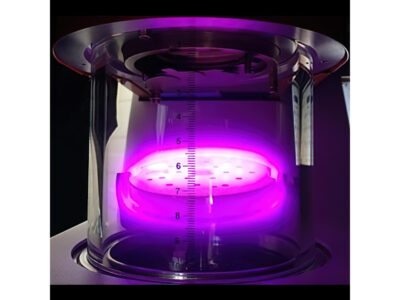

The glass vacuum chamber is 120mm in diameter and includes a handy vertical graduated scale for setting the height of the specimen stage. An implosion guard with safety monitoring is also fitted.

- Fully automated standard vacuum carbon coater

- Pulsed carbon evaporation for finer coating

- Standard and gentle operating modes

- Self-contained, plug-in style coating modules

- Multiple carbon coating runs before source change

- Dual-location quartz crystal film thickness monitor

- Intuitive, touch-screen control

- Easy upgrade to add high resolution coating

- 100mm diameter chamber with simple upgrade to large chamber (150mm/6″ specimens)

- Superb Swiss quality and reliability

CT-010 carbon coating module

The Safematic CT-010 carbon coating module is a unique carbon fibre evaporation system – featuring a proprietary (patented) automatic carbon fibre spooling system combined with pulsed evaporation.

The CT-010 automatically advances the carbon thread after each evaporation enabling up to 50 carbon coating runs without the need to change the carbon fibre source – a huge advantage over labour intensive single shot or double shot carbon coaters.

The CT-010 features dual carbon coating modes to suit requirements:

- Standard carbon coating mode for most routine carbon coating applications

- Gentle carbon coating for very thin films and/or temperature sensitive samples

FTM film thickness monitor

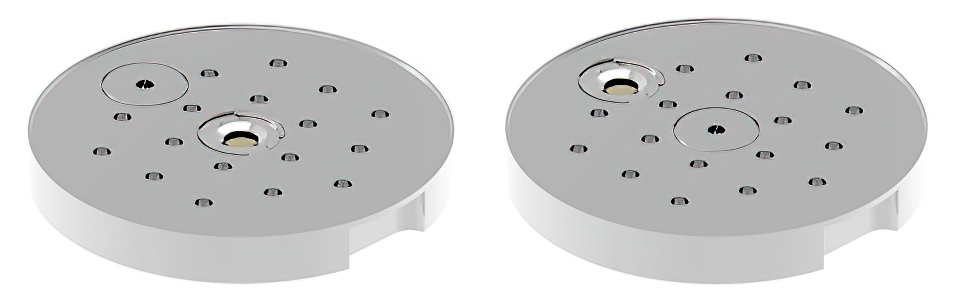

A dual-position film thickness monitor (FTM) measurement system monitors and terminates the coating process at a user-defined thickness.

The plug-in monitoring quartz crystal and holder can be moved between the centre of the specimen stage and the outside, to accommodate different specimen sizes and layouts.

Vacuum pumping requirements

CCU-010 LV requires a suitable two stage rotary vacuum pump. With high performance, reliability and low noise characteristics, an Edwards RV3 is ideally suited for this purpose. please see Ordering Information (below) for details.

- Configuring the CCU-010HV

- Specimen stages

- Accessories

- Glow discharge options

- Software options

- Remote control

- Specification

- About Safematic

To configure a working CCU-010 LV standard vacuum carbon coater you will require the following:

- CCU-010 LV base unit inclusive of a standard specimen stage

- CT-010 carbon head module

- Optional alternative specimen stage such as RS-010 or PS-006

- Other optional accessories as required

Please add your required items using the quote buttons below and we will endeavour to provide your quotation as quickly as possible

Rotation and rotary planetary stages

A choice of easily exchangeable specimen stages, all with height and tilt angle adjustments, is available for the CCU-010 LV.

- CCU-010 LV includes a standard plug-in style 80mm diameter specimen stage.

- For specimens requiring rotation the optional RS-010 rotation stage is available.

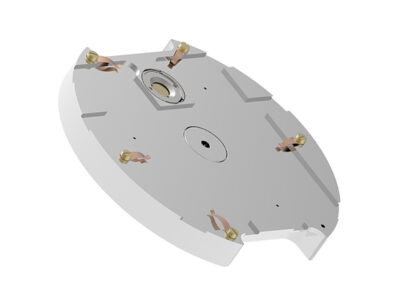

- For specimens with very irregular surfaces, or for particulates and spheres, the PS-006 rotary planetary stage is recommended.

3. Rotary Planetary Stage

1. Standard Stage

2. Rotary Stage

Weight: 0.2kg

Number of specimen stub holders: 20

Rotation direction:: Clockwise

Speed: 6-120 rpm

Weight: 0.2kg

Number of sample stub holders: 6

Rotation direction of table: Clockwise

Speed (specimen table): 0-20rpm

Rotation direction (specimen stub holders): Anticlockwise

Speed (specimen stub holders): 0-65rpm

HS-010 vacuum storage system

The HS-010 is a compact vacuum storage system that allows a second CCU-010 coating head, additional stage and sputter coater targets to be stored under vacuum when not in use. There is no requirement for a separate pump as the CCU-010 can be used to pump down the storage unit.

For further information please see: Flyer HS-010 head storage unit

GD-010 Glow discharge unit

The GD-010 is a plug-in glow discharge unit specifically designed for use with the CT-010 carbon thread evaporation head module.

It consists of:

- Height adjustable glow ring with shielding

- High voltage power supply

- High voltage plug-in connector

- Process gas plug-in connector

- Process pressure regulation valve

- Process gas connection through CT-010 carbon thread evaporation head

ET-010 plasma cleaning stage

The ET-010 plasma cleaning specimen stage is designed for the pre-treatment (or post-treatment) of specimens in combination with a coating process. Samples can be pre-cleaned to remove light hydrocarbon surface contamination prior to sputter coating or carbon coating without the need to break vacuum. The ET-010 can also be used for the hydrophobic to hydrophilic surface conversion of TEM carbon films using an air plasma.

Click here for detailed information: Flyer ET-010 etching unit

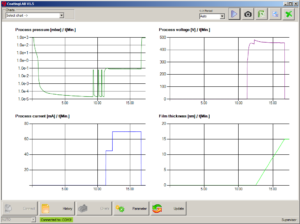

Coating Lab software provides easy access to comprehensive carbon and sputter coating and process data for audit or quality control processes.

The Windows-based software records key data as real-time curves in a graphical format: vacuum pressure, current, voltage, carbon coating and sputter coating rate, coating thickness and specimen temperature.

The CCU-010 LV is connected to a PC using a USB cable, with Coating LAB automatically establishing a connection to the coater. Password protected tools for configuring the system and updating the firmware are included.

RAM: 512MB

Memory 32 Bit: 850MB

Memory 64 Bit: 2GB

System requirements SW

Server operating system: Windows Server 2012 R2, Windows Server 2012 (64-Bit-Edition), Windows Server 2008 R2 SP1, Windows Server 2008 SP2

RC-010 is Windows-based software that allows the CCU-010 to be remotely controlled and monitored from an external computer, for example when using the coater inside a glovebox. The GUI allows easy set up and selection of sputtering and carbon coating recipes and comes ready with user editable recipes with optimal settings for the most common metal sputtering targets and carbon evaporation. Connection from a laptop or computer to the CCU-010 HV coating system is via a USB cable.

Minimum system requirements:

Windows 10, Windows 8.1, Windows 8, Windows 7 SP1, minimum 512MB of RAM, screen resolution 1024×768 or higher, USB 2.0 Interface

Brochure download:RC-010_remote control software.

Dimensions

Dimensions (unpacked): L 570 x W 360 x H 350mm. 25kg

Glass cylinder: Ø 120mm (DN 100 ISO-KF compatible)

Implosion guard: Plastic splinter shield around the glass cylinder

Carbon source: 2m carbon fibre tread on as spool (300015)

Targets (for SP-010 option): Ø 54mm and thickness up to 3mm

Coating time: 0.5 to 990s

Coating current: 10-100mA

Pumping: Edwards RV3 50/minute rotary vaccum pump with oil mist filter

Ultimate vacuum: <10-2 mbar

Vacuum measurement: Pirani and cold cathode gauges

Display: 115 x 86mm, TFT graphical display

Specimen stage: Ø 80mm, height adjustment 0-50mm, tilt 0-45°

Film thickness measurement: Dual-position film thickness monitoring system. Piezoelectric crystal: frequency 6MHz, Ø 14mm, thickness 0.4mm.

Electrical: Plug C14, 90-260VAC, 47-63 Hz, 500W

Process gas connections: Process gas: Ø 6mm, venting gas: Ø 6mm, plasma gas (for optional SP-010 sputtering head module): Ø 6mm

Electrical: Connector socket C13, secured with 10A therm. circuit breaker

Located in Switzerland’s St. Gallen Rhine Valley – a region long renowned for expertise in vacuum and coating technology – Safematic GmbH manufactures technology-leading, highly innovative vacuum coating systems for electron microscopy and thin film applications. Labtech is delighted to offer Safematic sputter coaters, carbon coaters and accessories to our customers in the UK and Ireland.

Carbon coater ordering information:

Base unit and carbon coating module

To configure a working CCU-010 HV system please add the base unit and carbon head module to your quote and then add any other accessories from the list of options below:

-

CCU-010 LV (standard vacuum)

Safematic CCU-010 LV compact, fully automatic, standard vacuum coating system.

Price On Request £0.00 Add to basket -

CT-010 carbon coating module

Carbon fibre thread evaporation module with unique thread tracking system, allowing up to 50 coatings without having to break vacuum and replenish the carbon source. Controlled, automatic pulse evaporation modes give optimal coating control and film quality. Easy-fit electrical and pneumatic interface to CCU-010 LV and CCU-010 HV platforms. Includes one 300015 carbon thread on coil 2m.

Price On Request £0.00 Add to basket

Large chamber option – for samples up to 6″ (152mm) in diameter

The LC-006 is a large chamber option that replaces the standard glass chamber and allows specimens up to 6” (152mm) to be coated.

A sample holder for 6” wafers is included, other holders can be fitted. The LC-006 can be retrofitted to existing CCU-010 coaters.

-

LC-006 large chamber for CCU-0010 coaters

The LC-006 is a large chamber option that replaces the standard glass chamber and allows specimens up to 6” (152mm) to be coated. The chamber is made of aluminium therefore does not require an implosion guard. The LC-006 includes a sample holder for 6” wafers, but other holders can be fitted.

Price On Request £0.00 Add to basket

Rotary pump and fittings

If supplying separately or using an existing pump, it should have a pumping capacity of 50L/m or greater

-

Edwards RV3 rotary vacuum pump (including Ultragrade oil) with 2m UK mains lead

Edwards RV3 two stage rotary vacuum pump

Price On Request £2,413.00 Add to basket -

EMF10 mist filter

Edwards EMF10 oil mist filter suitable for use with an RV3 pump. Supplied with NW25 clamp, centering ring and O- ring- NW25 to 3/4 inch BSP adaptor.

£348.00 Add to basket -

NW25 braided flexible pipeline stainless steel 1000mm

Flexible metal vacuum hose with connecting clamps, O-rings and O-ring carriers

£358.00 Add to basket

Specimen stages

Please select additional specimen stages from the options below

-

RS-010 rotary table

Plug-in style rotary specimen table with smooth adjustment of table height, tilt angle and rotational speed. The 80mm diameter stage has locations for up to 20 standard (13 mm) SEM pin stubs or five 25mm stubs. On request other sizes and styles of SEM stubs can be accommodated.

Price On Request £0.00 Add to basket -

PS-006 planetary gear table

Consisting of base plate for connection to the tilt and height adjustable specimen table of the CCU-010 base unit. Specimen holders for six large (Ø 25.4mm) or six small (Ø12.7mm) SEM pin stubs. DC micro-motor for rotation and planetary movement, quartz sensor (centre), speed control: 0-100%, rotation: 0-20rpm approximately, planets: 0-65rpm approximately

Price On Request £0.00 Add to basket -

ST-010 object slide table

ST-010 specimen stage for microscopy slides. Comprises base plate connected to the tilt and height adjustable specimen table of the CCU-010 base unit. For two microscopy slides 76 x 26mm or one slide 76 x 52mm. Can also be used for coverslips. Twelve M2 threaded holes for S-clips. Two FTM quartz crystal positions (centre and edge). Six mounting clips M2 included.

Price On Request £0.00 Add to basket -

Rotary support for PS-006

Rotary support for use with the PS-006 planetary gear stage. Includes slip-on specimen holder which converts the planetary gear stage into a rotary stage. Twelve M2 threads for mounting specimens or for the using S-clips. Six mounting clips M2 included.

Price On Request £0.00 Add to basket

Glow discharge and plasma cleaning

Safematic offer a choice of glow discharge / etching options for the CCU-010 HV carbon coating unit

-

GD-010 glow discharge

Glow discharge attachment for hydrophilic/hydrophobic treatment (rendering) of substrates (e.g. TEM carbon support films). Fully integrated to allow post-treatment of carbon films without the need to break vacuum after carbon coating

Price On Request £0.00 Add to basket -

ET-010 integrated plasma stage

Plasma cleaning accessory for the pre-treatment (cleaning) or after-treatment (glow discharge effect) of specimens in combination with a coating process.

Price On Request £0.00 Add to basket

Remote control software and Coating LAB

Safematic offer software options for retrieval of coating data for audit purposes or for remote control of the instrument

-

Coating LAB software

Coating LAB Windows-based software can be installed on a laptop for monitoring and documenting coating processes. Fully automatic logs and charts containing all process-related data can be exported as screenshots or CSV files for Office applications. Available information includes process vacuum, current and voltage along with film thickness and coating rates (Internet connection required). Coating-LAB will allow remote service access for error diagnosis and process optimisation.

Price On Request £0.00 Add to basket -

RC-010 software for remote control of CCU-010

Windows-based RC-010 remote control software allows Safematic CCU-010 coaters to be run remotely for the control, monitoring and analysis of coating processes, for example in a glove box. The RC-010 comes ready with pre-defined recipes with optimal settings for the most common metal sputtering targets as well as for carbon. Requires connection from a laptop or computer (not supplied) to the CCU-010 coating system via a USB cable.

Price On Request £0.00 Add to basket

Head module storage

For combined coating systems with more than one coating head module a storage unit can be used to store the one not in use under vacuum.

Replacement carbon fibre

Additional carbon thread on a spool